What you should know about electrical system oversight

The impact of an equipment breakdown can extend beyond the immediate loss to the equipment itself. Downtime, delays, and disruption ripple through operations, at times costing far more than the repair itself.

The most valuable insights come from the losses we had the power to prevent. This real-world loss scenario drives home a critical truth: preventive maintenance isn’t optional—it’s essential.

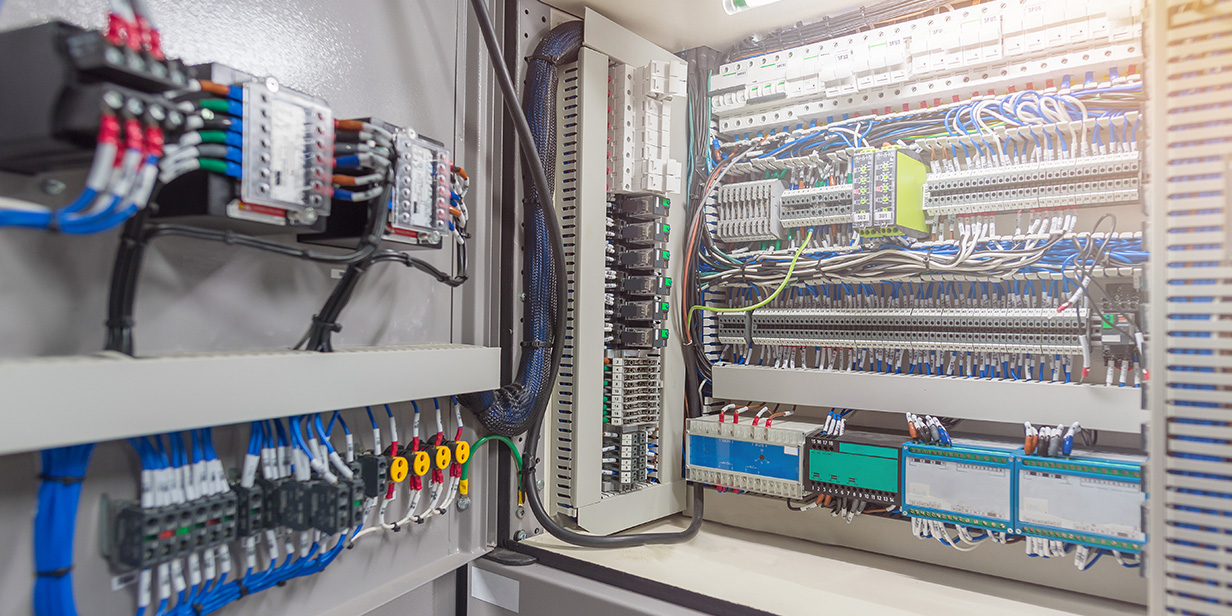

A sudden power surge damaged an electrical switchgear, a key component in the electrical distribution system. Electrical arcing inside the unit caused severe discoloration and melted bus bar connections—clear signs of intense heat and neglect. Observations from a consulting firm’s inspection revealed that the damaged switchboard had not been properly maintained during its service life.

Electrical systems can break down due to loose connections, heat buildup, and missed warning signs. In this case, the breakdown occurred at one of four bus connectors inside an outdoor switchboard. These connectors are critical for maintaining tight, reliable contact within bus bar connections. Over time, they loosen, creating gaps that invite arcing and damage.

To keep operations running, the insured rented a generator. However, finding an electrical contractor to make the repairs took months. The result: nearly 150 days of open claims activity, mounting rental fees, and a final extra expense nearly six times the cost of the actual repair.

Understanding heat buildup in high-current systems helps underscore the importance of regular maintenance.

As electrical connections loosen, and similarly, as points of corrosion develop, resistance increases at the contact points. Maintenance-related issues such as dust accumulation, oxidation, and mechanical wear further degrade conductive surfaces, compounding the problem. This increased resistance generates heat, which accelerates the breakdown of surrounding insulation and materials, compromising the integrity of the connection. In high-current systems like switchboards, even minor resistance can lead to significant thermal buildup, causing metal fatigue, insulation failure, and ultimately arcing. Arcing not only damages the component but also poses a serious fire risk and can trigger cascading failures throughout the system. Beyond the immediate hazard, operating electrical components at elevated temperatures significantly shortens their functional life expectancy, often resulting in premature failure and extended downtime.

The solution: Proactive, not reactive

Here’s what could have prevented this loss and what every property owner can do to stay ahead of risk:

- Conduct daily “hands-off” inspections: Look, listen, and smell for signs of trouble—heat, noise, vibration, or odor.

- Schedule routine “hands-on” inspections every 3–5 years by licensed electricians: Include infrared thermography, breaker testing, and insulation resistance checks.

- Follow manufacturer guidelines for all electrical components: switchgear, panelboards, transformers, and emergency transfer switches.

- Implement formal preventive maintenance programs: Establish consistent procedures and timelines for inspection and servicing.

- Document all inspections and repairs: Maintain clear records to support accountability and future decision-making.

- Partner with qualified electrical professionals: Ensure all work is performed by licensed, insured experts with experience in complex systems.

Downtime from electrical breakdowns doesn’t just add to the total cost of a claim—it can significantly disrupt operations. Extended delays can lead to lost revenue, reputational damage, and strained customer relationships. While insurance is designed to provide financial protection, loss prevention is the key to minimizing the impact of these events.

Share this with your insureds to help them avoid costly breakdowns.

Additional resources:

- Electrical breakdown

- Risky business – Electrical preventive maintenance

- Contact us or login to FM Boiler Re Online for a copy of the Hazard Guide on Electrical Preventive Maintenance and/or Risk Indicators for Electrical Switchgear