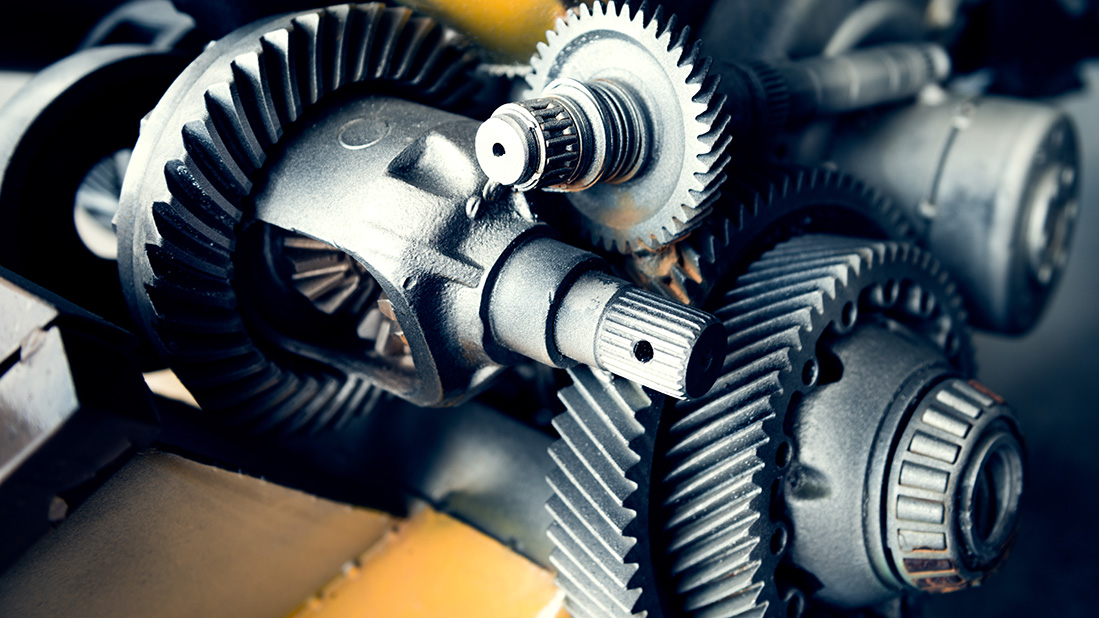

Mechanical breakdown

From a historical perspective, mechanical components and mechanisms that make up a whole mechanical system or machine have been around for centuries. A good example of an early man-made machine is the third century Hierapolis Sawmill, which utilized a water wheel to create the energy needed to move a slide-crank mechanism attached to a saw blade for cutting wood. All machinery and equipment operate by converting energy into motion using various moving parts, which are in turn designed to multiply the force on an object or material with the ultimate goal of making an end-product or providing a service. Examples of mechanical machinery include pumps, internal combustion engines, compressors, metal stamping presses, turbines, and fans/blowers.

Mechanical hazards

Mechanical hazards are conditions that develop with machines and equipment and increase the chance of them experiencing a mechanical breakdown event. The severity of the mechanical breakdown to a single machine can have a cascading effect on business interruption and allocation of business resources that would have otherwise been used to continue business operations.

Outlined below are mechanical hazards to consider:

- Lack of lubrication - Lubrication reduces friction between moving parts. Mechanical parts that do not receive enough lubrication create tremendous amounts of heat and can accelerate wear and premature damage, leading to a mechanical breakdown event.

- Misalignment - Incorrect alignment occurs when the centerlines of two different machine component parts are not in line with each other. Misalignment produces excessive vibration, audible noise, high bearing temperature and increased physical stress on surrounding and connected machine components. The objective of optimal alignment is to allow any machinery to operate within its acceptable design limits, which will increase reliability and operating life.

- Moisture/humidity - Prolonged exposure to condensation can cause rust/corrosion on moving parts. The erosion of materials from these parts creates degradation and malfunction leading to mechanical breakdown

- Imbalance/vibration - This occurs when a part does not rotate evenly around its center axis. Instead, the part rotates eccentrically or elliptically. The problem causes undue wear within the part and can lead to excessive vibration moving to other parts of the machine and early failure of the machine.

- Looseness - When an excess amount of clearance appears between connected moving parts, accelerated wear on the same parts can cause mechanical failure of the machinery or equipment.

- Oil contamination - Machinery and equipment rely on clean oil as a lubricant to reduce friction and heat between fast moving, closely fitted parts. Over time, oil degrades releasing organic compounds that can cause corrosion or rust. In addition, fine metal particles that are the result of regular machine use become part of the oil. If not removed by filtration, the metal particles can rub between other moving parts and create accelerated wear.

- Operator error - Machine operators have a formidable task of running machinery and equipment at its optimal level for repeated use. Sometimes, due to a lack of training and experience, machine operators may make adjustments to the machine that create excessive load demand beyond the capability of the machine.

- Overspeed - Machinery and equipment are designed by the manufacturer to operate at a pre-set range of speeds. When the operating speed of a machine is exceeded, the integrity of mechanical connections in machinery components can be overcome by the high level of stress as they move faster and faster during the overspeed event.

Loss prevention

- Preventive maintenance program - Maintenance should be scheduled proactively, based on either time, usage or condition. A typical standard for a well-maintained facility is for 85% of maintenance tasks to be performed proactively. Reactive, breakdown maintenance, or run to failure, can consequently lead to unexpected business interruption.

- Machine operator training programs - Machine operators are the first ones to notice when equipment is not working as designed. Properly trained operators can bring quality problems to a maintenance team's attention early in the wear and tear process to allow maintenance to correct the issue with minimal down time. Operator error is also one of the leading causes of mechanical breakdown losses.

Implementation of maintenance and training programs can help business owners prevent loss to critical machinery and equipment, in addition to costly downtime. Maintenance is designed to maximize reliability, safety, energy efficiency, and decrease the potential for breakdown.

Additional resource: