Under pressure: Bursting at the seams

Steam boilers are used in a wide range of industries and buildings due to their versatility and efficiency. Applications range anywhere from providing heat for an apartment building to driving a large turbine generator in an electric utility power plant. When properly maintained, they are extremely reliable. The stored energy in steam boilers can be harnessed for many applications, but this can also create dangerous conditions when equipment fails. A sudden rupture of pressure retaining components can cause catastrophic damage and serious harm to personnel. Proper maintenance, testing of safety devices, and training of operators are critical for ensuring safe conditions and preventing these catastrophic events.

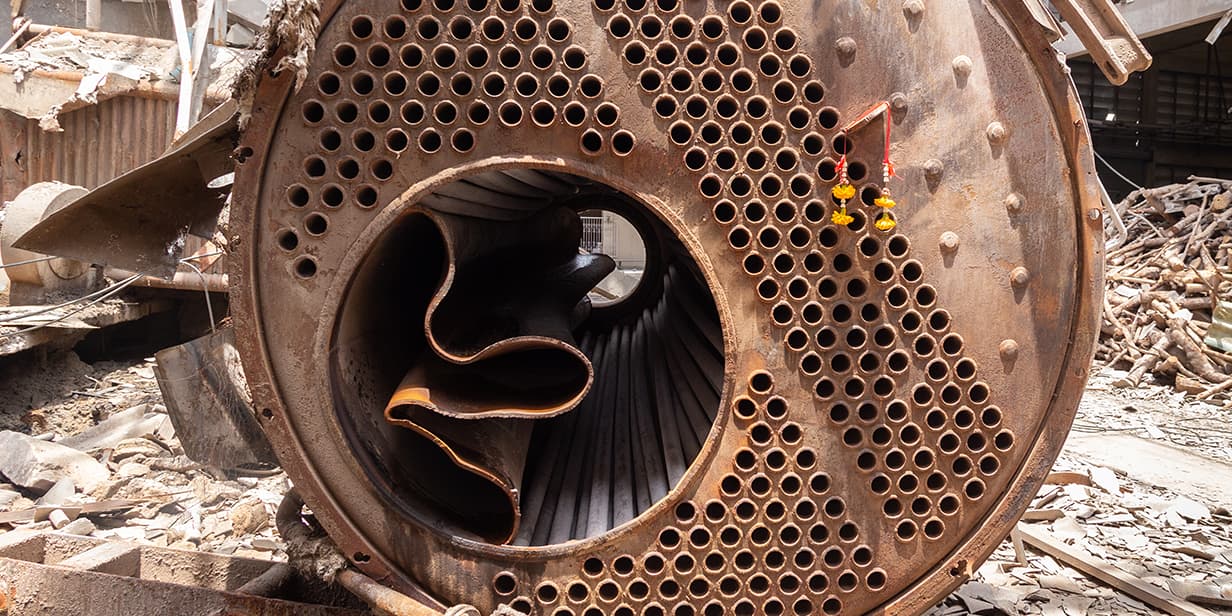

A pressure explosion occurs due to the failure of a pressure part of the boiler that contains the steam and water side. This causes a sudden release of expanding steam and water. This rapid release of pressure can lead to the boiler rupturing and exploding, causing significant damage to the boiler and surrounding area.

Preventing pressure explosions

Boiler codes and jurisdictional inspection laws require certain safety devices to be installed on boilers to protect against low water, overheating and overpressure conditions. It’s imperative that these safety devices are properly installed, maintained and tested. A comprehensive boiler maintenance schedule should be followed that adheres to the National Board Inspection Code, state jurisdictional regulations and requirements, and OEM recommendations. Boiler operators and owners should also be well trained, and properly certified and licensed in jurisdictions that require it. Here are some general loss prevention steps:

- Conduct routine inspections in accordance with OEM recommendations and state and jurisdictional requirements. Most boilers are required by state boiler laws to be regularly inspected by a commissioned inspector.

- At least annually, clean boiler waterside surfaces of scale and sediment, and fireside surfaces of accumulated soot and deposits.

- Test critical safety devices like the low water cutoff and pressure relief valves to ensure they are functioning properly.

- Maintain good water chemistry by regularly testing and treating the boiler water to prevent scale buildup and corrosion. This involves monitoring pH levels, hardness, and dissolved solids.

- Follow a comprehensive maintenance schedule that includes weekly, monthly, quarterly and annual tasks to keep the boiler in optimal condition.

- Ensure boiler owners and operators are adequately trained and qualified to operate and maintain the equipment they are responsible for. This includes ongoing training. In jurisdictions with licensing requirements, operators must obtain and keep current any mandatory certifications or licenses.

What about other pressure vessels?

Hot water boilers and hot water heaters are also susceptible to pressure explosions. While incidents are rare compared to steam boilers, these vessels do contain water under pressure. Improper installation, or a malfunctioning temperature and pressure (T&P) relief valve on a hot water heater can lead to the temperature and pressure inside the tank to build up to a dangerous level. Proper maintenance, regular testing of the T&P relief valve, as well as periodic flushing of the tank to remove sediment, will help reduce the risk of failure.

Other unfired pressure vessels such as air tanks and water storage tanks can also experience a pressure explosion under certain circumstances. Maintaining and testing the pressure relief valve, preventing corrosion of the vessel shell, and not exceeding the useful life of the vessel’s structural integrity are good loss prevention steps to follow.

Is a combustion explosion the same as a pressure explosion?

A combustion explosion within a boiler, also known as a firebox explosion, occurs when unburned fuel and air is allowed to accumulate in the firebox area, and is eventually ignited. This ignition of the confined fuel-air mixture leads to a rapid and uncontrolled release of energy, causing a sudden pressure increase and shockwave inside the furnace. While this can damage the furnace and boiler structure, it is generally less catastrophic than a pressure explosion. Both types of boiler explosions are hazardous, but they stem from different causes and mechanisms. Proper maintenance, testing and safety protocols are essential to prevent these types of dangerous incidents from occurring in boilers.

Additional resources:

- Risky business infographic – boilers

- Understanding the Hazard: Boiler and pressure vessel overpressure – available in the FM Resource Catalog

- Understanding the Hazard: Boiler overheating – available in the FM Resource Catalog